Most people love the cozy comfort of sheepskin boots—but few know what really goes into making them. I’ve worked behind the scenes, and there’s more to the story than meets the eye.

Sheepskin boots are made through a careful process involving eco-certified materials1, small-batch production lines, and detailed customization based on customer designs.

I’ve followed these boots from design sketches all the way to international shipping containers2, and each step reveals something unique about how quality footwear is made today.

[Table of Contents]

What kind of materials are used in sheepskin boots?

We don’t just pick any leather or fur off the shelf. Good materials are the heart of a comfortable boot.

We use real double-faced sheepskin3, eco-friendly dyed suede4, and tested rubber or EVA soles5, often certified for quality and safety.

We partner only with factories that meet international compliance standards6. That means every batch of wool or suede must pass quality and safety tests. For example, some of our materials come with OEKO-TEX7 or REACH certifications8. These are especially important for customers like Amelie—a fashion designer who needs both sustainability and high-end appeal.

Material Comparison Table

| Material | Feature | Certification | Why We Use It |

|---|---|---|---|

| Double-faced sheepskin | Soft, breathable, insulating | Often REACH/OEKO-TEX | Luxury feel and warmth |

| Eco-dyed suede | Flexible, durable, low-impact dye | REACH | Reduces harmful chemical use |

| EVA soles | Lightweight, cushioning | SGS-tested | Ideal for comfort and durability |

How are customer designs turned into final products?

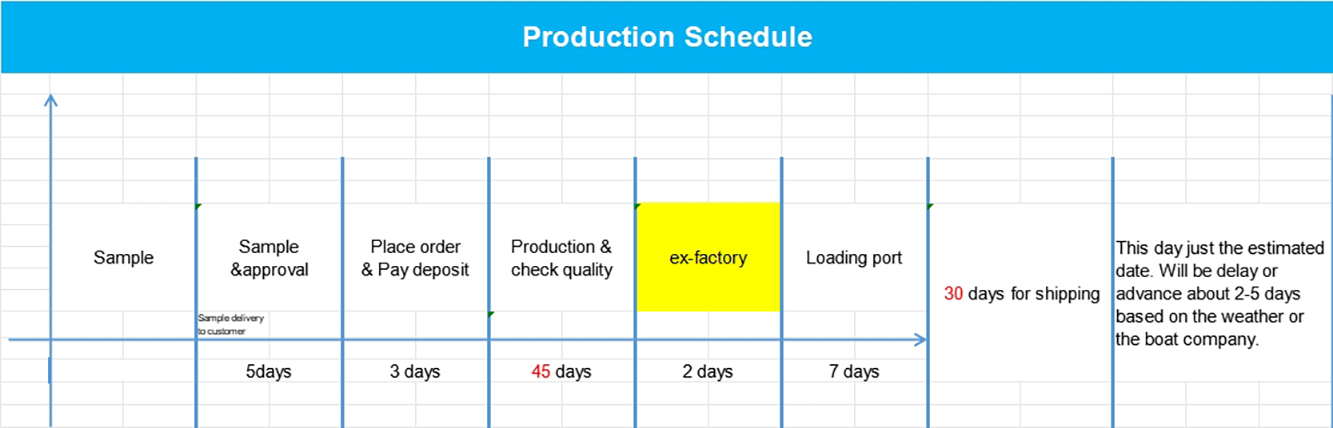

When a customer sends in a design, we don't jump into production right away. We follow a few clear steps.

We translate design files into tech packs9, choose a matching production line, and send pre-production samples for approval.

Our clients range from young trendy brands to traditional wool distributors, so customization needs vary. For instance, “Rural” sends us low-MOQ trending styles with their logo, while “Andy” prefers classic wool looks. We create a tech pack—a document detailing material, dimensions, and stitching—for each order. Then we assign it to the right factory based on skill and equipment. Only after sample approval does bulk production begin.

Sample Production Flow

- Client sends sketches or sample reference

- We prepare a tech pack

- Factory creates a prototype

- Client confirms sample

- Production line starts

What makes small-batch production possible?

Most factories don’t like small orders—but we’ve made it work.

We work with flexible factories who accept low MOQs10, using modular production setups and detailed tracking to keep quality consistent.

Many of our partners are small, stable factories we’ve worked with for over 10 years. These factories are open to small orders if the production process is clear and materials are in stock. This flexibility helps clients like “Rural” who only want 100-300 pairs of a trending boot. We break orders into modules: upper cutting, sewing, sole pressing, and assembly. That way, different factories can work simultaneously without delay.

Example: Small-Batch Custom Order

| Step | Action Taken | Factory Type |

|---|---|---|

| Upper Design | Custom suede cut + label insert | Small pattern workshop |

| Assembly | Sewing and attaching soles | Main assembly line |

| Packaging | Custom printed box + hangtag | Branding line |

How do we manage quality control and delivery?

Getting it made is only half the job. Getting it right and on time is the real challenge.

We use a step-by-step SOP11 to track production progress, review photos from every batch, and check final QC before delivery.

Some of our clients, like Amelie, work with very complex products. We learned early on that communication gaps can cause big delays. So now, we follow a strict SOP that includes real-time updates, confirmation photos, and mid-production checks. For urgent cases, we even send video walkthroughs. Then, once everything’s packed, we work with our logistics partners12 for door-to-door shipping, especially helpful for cross-border e-commerce clients.

QC Process Overview

| Stage | What We Check | Tool Used |

|---|---|---|

| Mid-production | Stitching, logos, sizing | Photo & video checks |

| Final Inspection | Overall appearance, packaging, label | In-person + checklist |

| Shipping Prep | Carton weight, box count, documentation | Partnered logistics firm |

Why does this production process matter to buyers?

Buyers don’t want surprises. They want consistency, fast responses, and custom solutions.

This setup helps brands launch faster, reduce errors, and stay flexible even when trends shift or seasons change13.

In fast fashion or small-brand retail, things move quickly. By offering custom solutions with short turnaround times and small MOQs, we give our clients an edge. For example, Andy relies on our off-season stock strategy to reduce costs, while Amelie benefits from our ability to handle dozens of SKUs at once. In the end, production is not just about making boots—it’s about helping brands grow.

Conclusion

Making sheepskin boots is a mix of art, skill, and logistics. When done right, it helps brands move faster, cut waste, and deliver style with comfort.

Footnotes

-

Eco-certified materials ensure reduced environmental impact and are often a requirement for sustainable fashion brands. ↩

-

International logistics processes are complex and critical to cross-border e-commerce success. ↩

-

Double-faced sheepskin is valued for warmth and comfort, ideal for premium boots. ↩

-

Eco-friendly suede reduces environmental impact during dyeing and finishing processes. ↩

-

EVA soles are lightweight and shock-absorbing, frequently used in comfort footwear. ↩

-

International compliance standards like ISO, REACH, and OEKO-TEX help ensure safety and quality in manufacturing. ↩

-

OEKO-TEX certification indicates textiles are tested for harmful substances. ↩

-

REACH compliance ensures material safety according to European regulations. ↩

-

Tech packs are essential in apparel and footwear manufacturing to communicate specifications. ↩

-

Low MOQs (Minimum Order Quantities) allow small brands to test products without overcommitting. ↩

-

Standard Operating Procedures (SOPs) help streamline communication and maintain consistent quality control. ↩

-

Reliable logistics partners are key to timely and cost-efficient global delivery. ↩

-

Agile production setups allow brands to quickly adapt to changing consumer trends and seasonal demands. ↩