Tired of choosing between comfort, style, and customization in your footwear? You're not alone—and I’ve been there too.

Our custom clogs1 offer the perfect mix of comfort, design flexibility, and low minimum order quantities—tailored for brands that want to stand out without overspending.

I remember one client who had amazing ideas but couldn’t find a factory willing to make small batches. That’s when they found us—and never looked back.

[Table of Contents]

What Makes Our Clogs Different from Mass-Produced Ones?

Most factory shoes2 look the same and feel generic. That’s a problem if you're trying to build a brand.

We offer made-to-order clogs with brand logos, trending styles3, and renewable materials4—without needing to commit to thousands of units.

Let’s look at the key areas where our clogs stand out.

Customization Options

| Feature | Our Clogs | Mass-Produced Clogs |

|---|---|---|

| Branding | Fully Customizable | Generic or Fixed |

| Styles | Trend-Inspired | Basic, Repetitive |

| MOQ | Low (great for new brands) | High (only for large orders) |

We understand how complex your product details can be—like unique color combinations, eco-material4 requests, or irregular size runs. We've worked with high-end designer brands and fast-paced trend sellers, so we’re used to that kind of challenge.

Can Small Brands Really Order Custom Clogs from Us?

Yes. We’ve structured our business model5 around small and medium-sized brand needs.

We offer low MOQ6 orders for trending clog styles, including logo customization, helping smaller brands compete with larger players.

One of our clients, a trendy U.S.-based brand, used to get turned away because their order size was “too small.” But with us, they launched five new SKUs with custom branding in just one season.

Here’s how we support small businesses:

Our Advantages

- Low MOQ6: Start with a small order to test your market.

- Production Flexibility: We match you with the right factory based on your needs.

- Speed: Fast turnaround and updates at every step.

- Support: We guide you through sourcing, production, and delivery.

How Do We Ensure Reliable Production and Quality?

Custom orders can get messy without the right process. Miscommunications happen. Deadlines get missed.

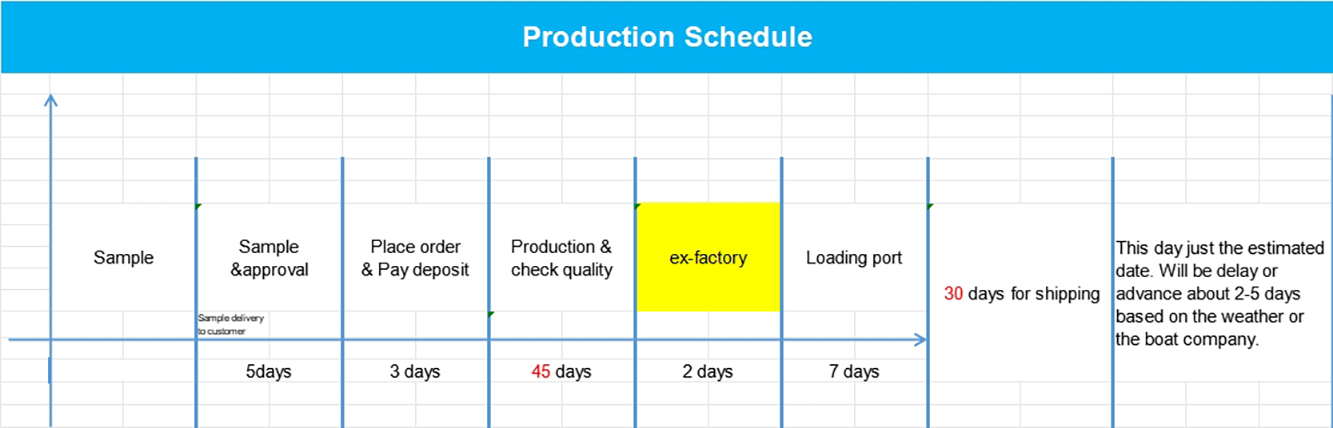

We maintain tight control over the production process by working with long-term, trusted factories7 and having a clear SOP8 for each project.

Our partners include small custom factories and audited suppliers. Some of them have worked with us for over 16 years. Here's what makes this work:

Factory Coordination Table

| Factory Type | Role in Our Supply Chain |

|---|---|

| Small Custom Factories | Unique designs, low MOQ |

| Brand-Collaborative Units | High consistency and audit-ready practices |

| Wool-Specialized Partners | For winter clog materials and quality |

With each order, we help you confirm the design, choose the right material9, and schedule a realistic delivery date. Our team stays in touch with the factory and you—so nothing gets lost in translation.

What Kind of Brands Work Best with Us?

Not every brand is a perfect fit. But we’ve found that certain profiles thrive with our model.

We work best with brands that value trend-forward design3, need low-to-mid order volumes, and want a flexible, reliable partner.

Here’s a quick breakdown of ideal client profiles based on our experience:

Ideal Brand Types

| Brand Type | What They Need | Why We’re a Fit |

|---|---|---|

| Designer Labels | Unique design, small MOQ | We manage complexity and details |

| Trendy Online Shops | Fast turnaround, custom branding | We’re agile and responsive |

| Seasonal Distributors | Wool or eco-focus, stable pricing | Deep supply chain knowledge |

For each of these client types, we’ve solved specific pain points—from inconsistent communication to difficulty getting special materials. Our system helps them save time, reduce risk, and grow.

Conclusion

We combine style, flexibility, and production expertise to help your brand create standout custom clogs—even with a small order.

Footnote

-

Explanation of what makes custom clogs valuable for small and emerging brands looking for low-MOQ and branding options. ↩

-

Most mass-produced factory shoes lack individuality and are not suited for niche brand positioning. ↩

-

Trending styles help brands align with seasonal or viral fashion movements to stay relevant. ↩ ↩

-

Renewable materials support sustainability goals and appeal to eco-conscious customers. ↩ ↩

-

A business model structured around small batch production enables better service for niche or emerging fashion labels. ↩

-

Low MOQ (Minimum Order Quantity) helps small brands test markets without major capital investment. ↩ ↩

-

Long-term factory partnerships reduce production risks and help maintain consistent quality. ↩

-

SOP (Standard Operating Procedures) help eliminate miscommunications and keep custom orders on track. ↩

-

Material selection is critical to achieving product quality and sustainability goals. ↩