Slipper brands face a big question when scaling: Do I produce in-house or work with an OEM manufacturer1?

OEM slipper manufacturing1 means working with a factory that produces slippers based on your designs and branding, allowing you to scale your product line without running your own factory.

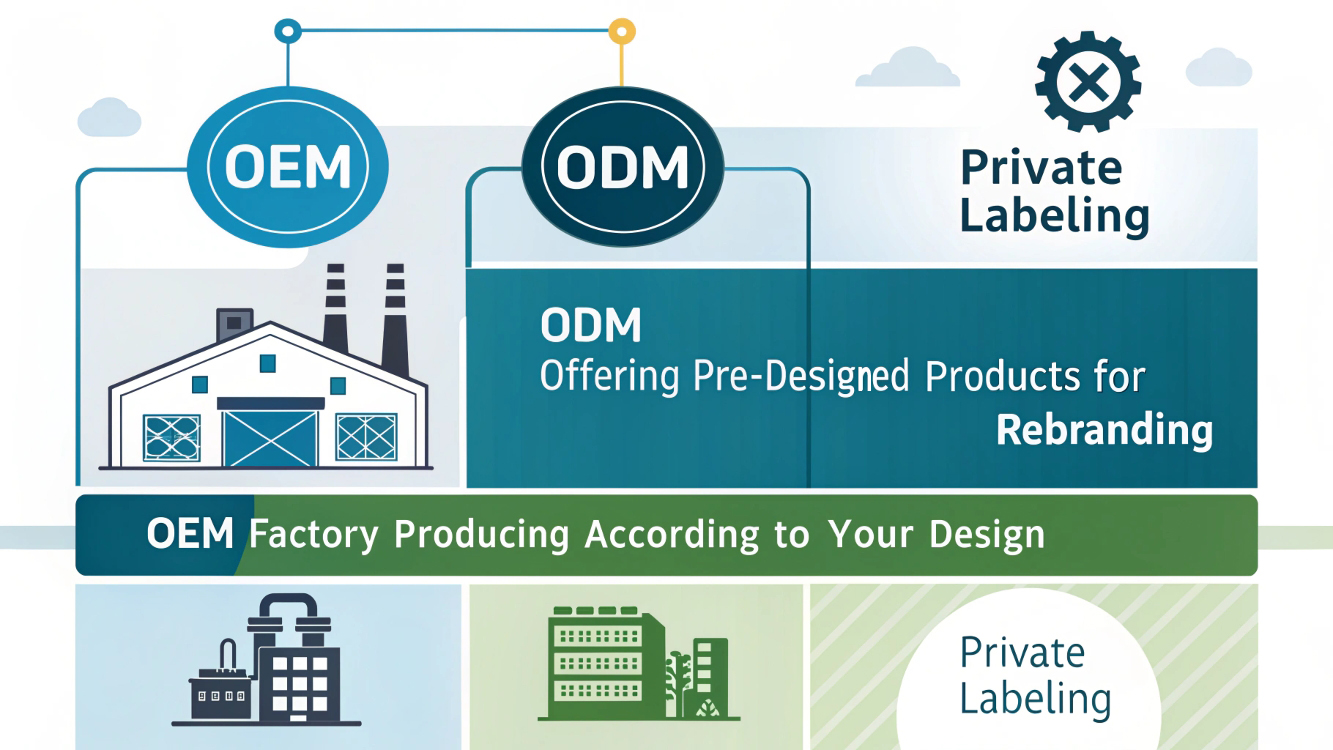

How is OEM different from ODM or private label?

Many buyers confuse OEM2 with ODM2 or private label2. I used to do the same.

OEM (Original Equipment Manufacturing)1 means the factory produces according to your design. ODM (Original Design Manufacturing) offers pre-designed products you can rebrand. Private label often means putting your logo on an existing product.

What are the benefits of OEM slipper manufacturing?

OEM sounds complex, but it solves many pain points, especially for growing brands.

OEM lets your brand control design, quality, and materials while keeping production flexible and scalable3.

Customization Freedom

You can choose everything—shape, fabric, lining, packaging. If you want a wool slipper with recycled rubber soles and vegan fur, it’s possible.

Flexible MOQs4

Most factories prefer large orders. But we’ve built a network of flexible factories that accept low MOQs for trendy, fast-moving styles.

Better Margins

OEM avoids middlemen. That means better cost control and room for higher profit margins.

Scalable Production

I work with 8 long-term factory partners. We assign orders based on quantity and complexity, so brands can scale without switching suppliers constantly.

Is OEM a good fit for your business size and model?

OEM is ideal if you already have a product idea or brand identity and want full control over how your slippers look and feel.

What are the risks of OEM, and how do I manage them?

OEM isn’t risk-free.

OEM requires good communication, clear SOPs5, and a reliable supply chain to avoid production errors or delays.

Clear Product Specs

Many errors come from unclear instructions. We work with clients to finalize every detail before production—logo placement, fabric specs, color codes.

Transparent Factory Matching

We match your order with the most suitable partner—small batch or large-scale.

Sampling & QC6

We always recommend sample confirmation and sometimes 3rd-party inspections7.

Production Tracking

We track every stage—from material arrival to packing—to avoid delays.

Can OEM help my brand grow internationally?

Many of my clients started local, then expanded globally using OEM.

OEM allows you to scale your production while keeping your brand identity consistent across markets.

Each region has different testing and packaging standards. Our partner factories are already familiar with these, and we help new clients adapt easily, including eco compliance8 in the US market.

Footnotes

-

OEM (Original Equipment Manufacturing) means producing goods based on the buyer’s specifications and designs. ↩ ↩ ↩

-

OEM is custom-design manufacturing; ODM is factory-designed rebranding; Private Label is logo placement on standard products. ↩ ↩ ↩

-

Scalable production means your factory can adapt output based on demand without changing suppliers or sacrificing quality. ↩

-

MOQ (Minimum Order Quantity) is the minimum number of units a manufacturer will accept per order, crucial for small brands testing new products. ↩

-

SOPs (Standard Operating Procedures) reduce production errors and miscommunication with suppliers. ↩

-

QC (Quality Control) ensures products meet your required quality standards before shipment. ↩

-

3rd-party inspections help ensure product quality by involving an unbiased external agency. ↩

-

Eco compliance refers to adherence to environmental and safety standards, especially relevant for markets like the US and Europe. ↩