Many small brands want to order custom suede slippers but fear high minimum order quantities (MOQs)1. This is a common problem that stops them from moving forward.

You can order custom suede slippers in small quantities by working with suppliers that offer low MOQs, flexible factory allocation, and personalized customization services.

Ordering footwear is not as complicated as it looks. If you understand the steps, you can start small and still meet your brand’s needs. Let me walk you through the process.

What makes small-quantity custom orders possible?

Many buyers believe custom footwear requires big budgets and large quantities. This is a myth that discourages small brands.

Small-quantity custom orders are possible when suppliers work with small factories, flexible production lines, and experienced sourcing teams that understand the challenges of new or growing brands.

Small-quantity customization works because suppliers like us allocate orders to the right type of factory. Large-scale factories may reject small orders, but smaller factories can handle them if they have stable processes. For example, in my business we work with eight long-term factory partners, each with different production strengths. This flexibility allows us to match the right partner with the right project.

Key Enablers of Low-MOQ Orders

| Factor | How It Helps |

|---|---|

| Small partner factories | Accept lower quantities |

| Factory allocation | Matches order size to capability |

| Long-term partnerships | Build trust and flexibility |

| Custom branding options | Even small runs can look professional |

How do I start the custom order process?

Many buyers hesitate because they do not know what information to prepare before placing an order.

To start, prepare your design ideas, quantity expectations, and budget. A supplier will then guide you on feasibility, materials, and factory options.

From my experience, the first step is always about clarity. You do not need finished technical drawings, but you should know your style, preferred material, and target audience. Once you share this, we can suggest suitable suede materials, eco-friendly options2, and logo placements. For example, when working with a U.S. trendy brand, we took their rough sketches and helped shape them into factory-ready specs. The clearer the starting point, the smoother the process will be.

Step-by-Step Preparation

- Gather style references and design sketches.

- Decide on the number of pairs you need.

- Share brand details like logo and packaging preferences.

- Set a target price range.

- Discuss timelines for samples and delivery.

What happens after I confirm the order?

Many think once the order is placed, the supplier takes over and the buyer has no control. That is not true.

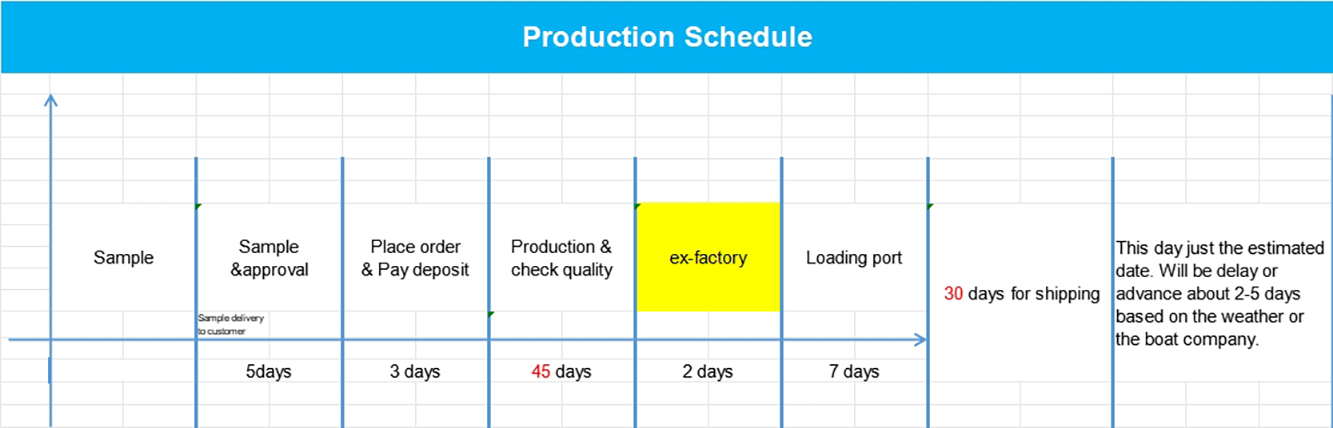

After confirmation, the supplier manages factory production, pre-production sample3 approval, and quality checks, while keeping you updated until delivery.

In my process, once you confirm, I allocate your order to a suitable partner factory. A pre-production sample is made and sent for your approval. If adjustments are needed, they are done quickly before mass production starts. Throughout the process, I track progress and provide updates. This prevents mistakes and delays, especially when order details are complex. For instance, one of my clients needed multiple colors and logo placements. By closely managing communication with the factory, I made sure everything matched before shipment.

Post-Order Workflow

| Stage | What Happens |

|---|---|

| Sample approval | Buyer checks design accuracy |

| Production start | Factory begins manufacturing |

| Quality checks | Supplier monitors compliance |

| Logistics | Door-to-door shipping arranged |

How do suppliers handle small quantity logistics?

Small brands often worry that shipping small orders will cost too much or be unreliable.

Suppliers with logistics partnerships can offer affordable, door-to-door delivery4 for small orders, saving time and reducing shipping risks.

In my experience, logistics is just as important as production. Many small brands are new to importing and do not know how to arrange shipping. That is why we partner with logistics companies that specialize in small-batch shipments. They can handle customs, duties, and even last-mile delivery. For example, a New Zealand wool distributor I work with relies on us for complete logistics support. They simply confirm the delivery address, and the products arrive at their door. This support allows small brands to focus on selling instead of worrying about shipping.

Logistics Options

| Option | Advantage |

|---|---|

| Air freight | Fast but higher cost |

| Sea freight (shared container) | Lower cost for bulkier orders |

| Door-to-door courier | Simplifies process for small brands |

Conclusion

Ordering custom suede slippers in small quantities is possible with the right supplier, clear communication, and strong logistics support.

Footnotes

-

Helps readers understand the concept of Minimum Order Quantity (MOQ) and why it is important for small brands. ↩

-

Guides readers who want to explore sustainable material options for their custom slippers. ↩

-

Clarifies the purpose of pre-production samples and why they are essential before mass production. ↩

-

Explains how door-to-door shipping works and why it benefits small brands ordering from overseas. ↩