When you want suede1 slippers with your own style, the challenge is usually finding suppliers who accept small orders. Most factories set high MOQs2, leaving small brands without options.

You can order small batches of custom suede slippers by working with suppliers that specialize in low-MOQ footwear production, provide design customization, and offer flexible door-to-door logistics3 support.

Many factories only take large wholesale orders. But I have learned that there are suppliers who accept small batches, especially if they understand the needs of small and medium brands. With the right partner, even 200–300 pairs can be enough to start production.

What is the process to order small batches of suede slippers?

When I started my own orders, I faced constant rejection because my quantities were too low. It felt impossible at first.

The process starts with sharing your design, confirming materials like suede1 and lining, setting a low MOQ with the supplier, then following up closely through production to shipment.

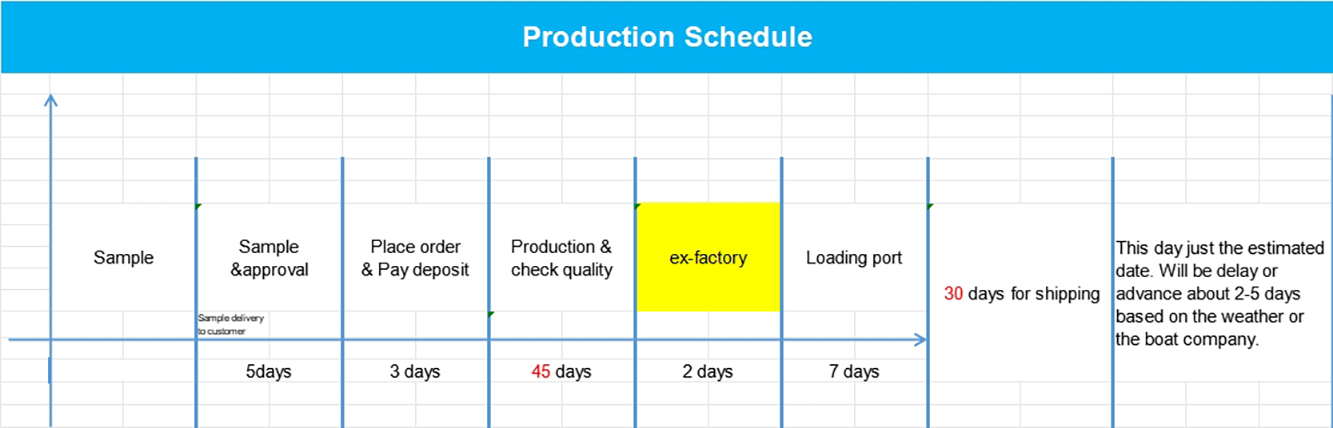

Ordering small batches usually follows a simple flow.

- Design submission – share sketches, mood boards, or reference shoes.

- Material selection – choose suede type, colors, inner lining, and outsole.

- Sample production – get 1–2 pairs made for confirmation.

- Batch production – agree on MOQ (often 200–300 pairs).

- Branding details – add logos, packaging, or labels.

- Logistics – confirm shipping method, often door-to-door logistics3 service for small brands.

I found that clear communication and fast sample approval speeds up everything.

Which suppliers accept small-batch orders?

When I was looking for the right partner, most factories told me no. They only wanted thousands of pairs.

Suppliers that work with small custom factories, brand-collaborative factories, or have low MOQ policies are best for small-batch suede slippers.

I discovered that suppliers like Yangzhou JNP Imp. & Exp. Co., Ltd. specialize in this. They allocate small orders to suitable factories that handle customization, and they already work with eco-friendly materials4 and audited partners. This matters because it gives confidence that quality and compliance are not sacrificed for small runs.

Here is how suppliers differ:

| Supplier Type | MOQ Range | Customization Level | Pros | Cons |

|---|---|---|---|---|

| Large factories | 1000+ pairs | Limited | Low cost per unit | Rejects small orders |

| Small custom factories | 200–300 pairs | Full customization | Accepts low MOQ, flexible | Slightly higher cost |

| Trading companies | Varies (300+) | Medium to high | Access to multiple factories | Middleman markup |

I found small custom factories the best choice, especially when guided by an experienced sourcing partner.

How can you customize suede slippers in small orders?

I used to think small orders meant no real customization. That was wrong.

Even with small orders, you can customize suede slippers by choosing colors, lining, outsole, logos, embroidery, and eco-friendly materials4.

Small batches can still be highly unique. For example, one of my clients chose pink suede with faux fur lining, and we added their logo on the insole. Another client wanted earth-tone suede slippers with a cork sole to match their eco-friendly brand image.

Common customization options include:

- Material: suede type (natural, vegan, or recycled)

- Colors: wide palette available even in low MOQ

- Linings: wool, faux fur, cotton, or microfiber

- Outsoles: rubber, EVA5, cork

- Logos: embroidery, deboss, or woven labels

- Packaging: branded boxes or eco-bags

I noticed that small trendy brands care most about colors and logos, while established distributors ask more about material certifications.

What are the costs and risks of small-batch suede slipper orders?

I worried about higher costs and delays before placing my first small-batch order.

Small batches usually cost more per unit, but risks can be reduced by clear communication, organized samples, and choosing suppliers experienced in small-scale customization.

The reality is that per-pair costs are higher compared to bulk orders. But the benefit is lower upfront investment, less inventory pressure, and quicker testing of new designs. I once ordered 250 pairs of suede slippers with custom branding. Even though the unit price was 20% higher, they sold out quickly, proving the design was worth scaling up.

Key risks include:

- Higher unit cost

- MOQ not met for some colors or materials

- Possible production delays if factory prioritizes larger orders

To reduce these risks, I always confirm every detail in writing, use suppliers with strong organizational skills, and request photos or videos of the production line.

Conclusion

Ordering small batches of custom suede slippers is possible with the right supplier. Small factories and low-MOQ partners open the door to real customization with less risk.

Footnotes

-

Suede is a type of leather made from the underside of animal skin, known for its softness and texture. ↩ ↩

-

MOQ means Minimum Order Quantity, which is the smallest number of units a supplier is willing to produce. ↩

-

Door-to-door logistics is a shipping method where the provider manages the delivery from the supplier’s factory to the customer’s destination. ↩ ↩

-

Eco-friendly materials are sustainable materials like recycled suede, organic cotton, or renewable cork, used to reduce environmental impact. ↩ ↩

-

EVA (ethylene-vinyl acetate) is a lightweight and flexible material commonly used in shoe outsoles. ↩