Dreaming of unique custom slippers but hit a wall with high MOQs? You're not alone. We make small-batch customization a reality, starting from just 100 pairs of stylish slippers.

We make 100-pair custom slipper orders workable by leveraging stock materials, offering limited technical customizations, and creatively balancing your design vision with available resources. This approach bypasses huge factory MOQs, making custom slippers accessible for emerging brands and small businesses looking for low MOQ options1.

The journey from a great design idea to a physical product can be frustrating, especially for small businesses. I had a conversation with a client just last week that perfectly illustrates this challenge—and our solution. It shows how we navigate the world of manufacturing to bring unique designs to life, even in small quantities. Let's dive into how we make it happen.

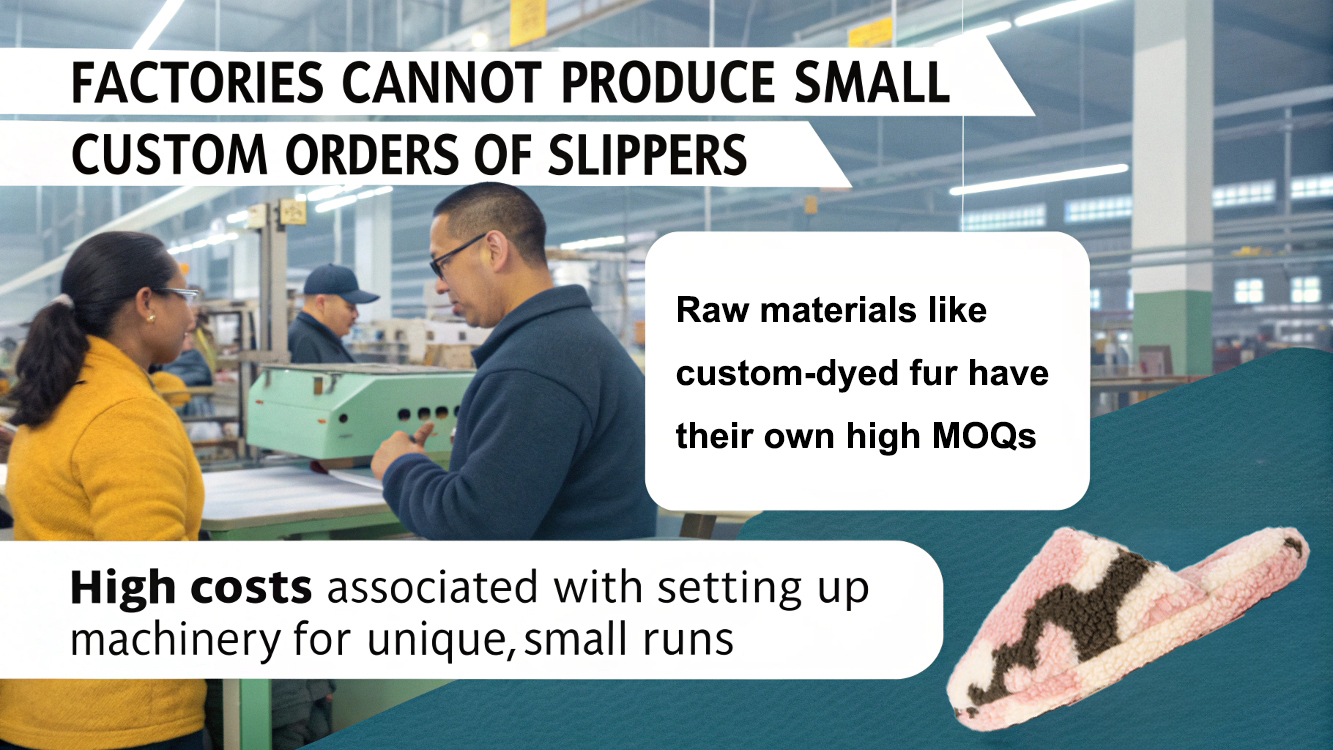

Why Can’t Factories Just Make 100 Pairs of Fully Custom Slippers?

You have a perfect design—the exact color, the ideal fur. But factories say no to your small order. It's frustrating when industrial logic clashes with creative ambition.

Factories can't make small custom orders because raw materials like custom-dyed fur have their own high Minimum Order Quantities (MOQs)2, often enough for thousands of pairs. The cost of setting up machinery for a unique, small run is simply too high for both the factory and the client.

Let’s break down the reality of the supply chain. The process doesn't start with me or the slipper factory; it starts with the raw material producers. For example, if you want a specific shade of faux fur that isn't already on the market, the fabric mill has to produce it for you. In a recent chat, I explained to a client that a custom fur order requires a minimum of 3,000 meters3. That much material can produce roughly 15,000 pairs of slippers. For a large brand, this is a standard order. For a startup or a small business testing a new design, it's an impossible number. This is the core reason why "full customization" is a game of scale. The economics only work with volume.

| Customization Aspect | Small Batch (100 Pairs) Challenge | Large Batch (15,000+ Pairs) Solution |

|---|---|---|

| Custom Fabric | Material MOQ is ~3,000 meters. | Easily meets and exceeds the material MOQ. |

| Machine Setup | High cost per unit to set up. | Setup cost is spread across thousands of units. |

| Labor | Skilled workers inefficiently used. | Efficient continuous production lines. |

| Price Per Pair | Extremely high due to overheads. | Optimized for wholesale pricing. |

So, What’s the Smart Way to Customize Slippers with a Low MOQ?

Told your dream design is impossible for a small batch? It feels like a dead end. But there's a creative workaround that balances your vision with practical production realities.

The smartest way is to start with high-quality stock materials4. We treat the market’s available fabric and color options as your creative palette. This strategy allows you to get unique, custom-branded slippers without the massive cost and quantity commitments of full customization, making it perfect for startups.

My job is not just to take an order; it's to be your production strategist. This starts with a simple question I ask every new client: "How many pairs do you need?" Your answer dictates our entire strategy. For an order of 100 pairs, we enter a partnership to bring your vision to life within the realm of possibility. I won’t ask you to sketch on a blank canvas. Instead, I become your personal shopper in the vast raw materials market. I’ll present you with a curated palette of beautiful, high-quality stock fabrics that are either trending or fit your brand’s feel. We must balance your idea and market stock5.

For instance, a client wanted a deep, dark-colored deer fur. That specific custom color wasn't available in stock. So, we found the closest existing shade that worked beautifully. The key is creative adaptation, not sacrifice. And customization is still possible—we can add your logo, use special stitching, or select a unique insole to make the final product truly yours.

How Do We Turn These Limitations into a Business Advantage for You?

Worried that using stock materials will make your product look generic? This fear holds many brands back. But this perceived limitation is actually a strategic advantage6 for speed and agility.

This approach turns limitations into advantages by enabling faster production times, lower financial risk, and the ability to test new styles quickly. By using ready materials, you can launch trendy, unique slippers faster than large brands locked into long, custom production cycles.

This agile approach is a game-changer, especially for clients like R., my online trendy brand customer. They need to catch trends as they happen. They can’t afford to wait months for a custom material to be produced, nor can they risk investing in 15,000 pairs of a style that might not sell. By using our "Agile Stock Model," they can launch a new slipper design in weeks, not months. They can test the market with just 100 or 200 pairs. If it sells out, fantastic—we can produce more quickly. If it doesn't, the financial hit is minimal, and they've gained valuable market data. This is how we apply successful e-commerce thinking to traditional manufacturing. It’s a huge advantage over bigger, slower competitors. At the end of my chat with the new client, they understood completely. Their reply was, "Maybe I could do something more simple. A stock color." That wasn’t a compromise; it was a smart business decision.

| Factor | Traditional Bulk Model | Our Agile Stock Model |

|---|---|---|

| Time-to-Market | 3–6 Months | 4–8 Weeks |

| Initial Investment | Very High | Very Low |

| Inventory Risk | High | Low |

| Flexibility | Low | High |

| Ideal For | Mass-Market Brands | Startups & Test Runs |

Conclusion

By balancing your design vision with market availability, we can bring your creative ideas to life. Let’s create your unique slippers based on popular, market-proven styles, ensuring they are both commercially viable and distinctly yours. We hope to have the opportunity to try this with you.

Footnote

-

For startups and small brands, finding manufacturers who accept low MOQs is key to launching products affordably. ↩

-

Explains why factories need large MOQs—setup costs and raw material constraints make small orders impractical. ↩

-

Shows how raw material producers like faux fur mills require high MOQs, not just the slipper factories. ↩

-

Starting with stock materials allows brands to skip massive investments while still getting a custom look. ↩

-

Balancing your idea with available stock is a creative workaround to traditional customization barriers. ↩

-

Agile production models reduce financial risk and improve speed to market for trendy, fast-moving brands. ↩