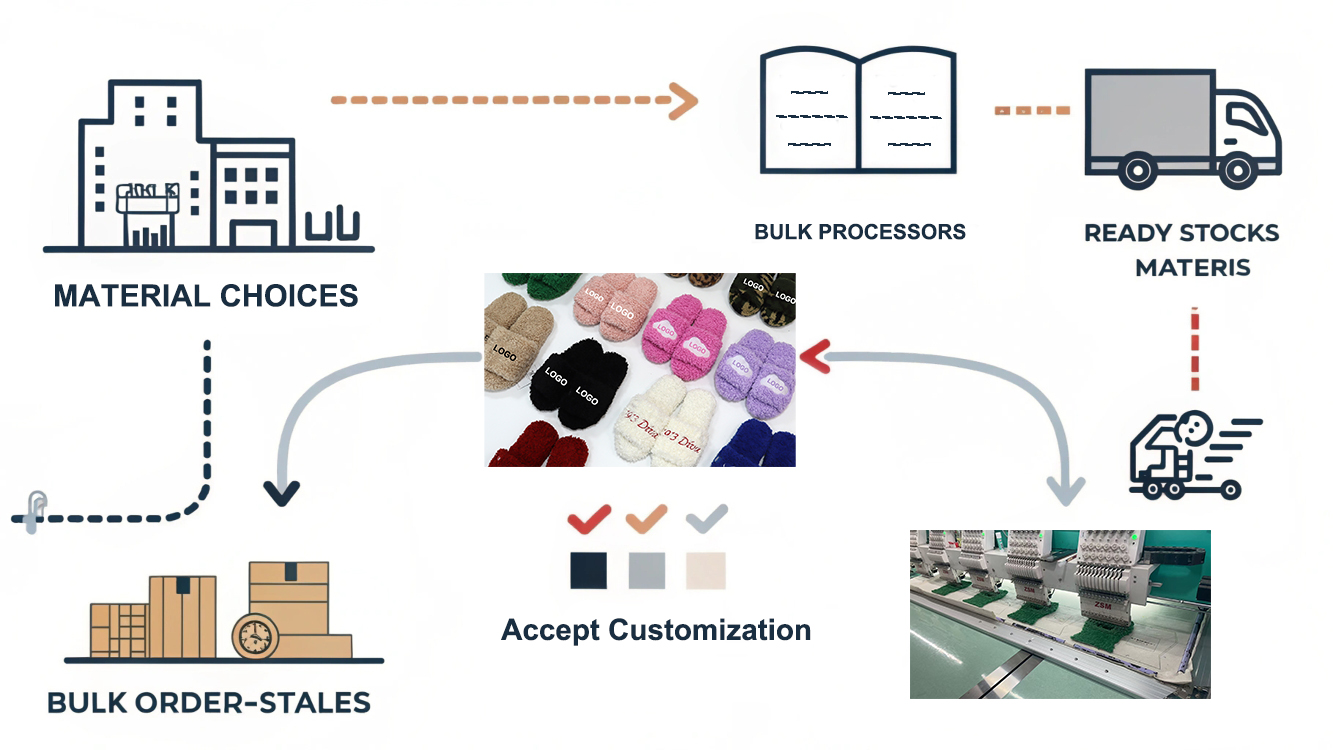

We often want unique footwear. Yet confusion about limited material choices and minimum quantity requirements can frustrate us. We need a simple roadmap to solve these problems. Custom footwear production1 involves balancing stock materials, technical processes, and bulk orders to meet unique brand needs. You can choose ready materials, partial customization, or large-scale orders based on quantity.

I once struggled to find the right slipper materials for a small collection. I discovered that quantity shapes customization. That moment opened my eyes. It set me on a path to explore practical solutions. Now I share these solutions so we can focus on making smart decisions that fit our exact needs.

Which Customization Approach Works Best for Small Orders?

Finding the right method for small orders can feel overwhelming. We fear expensive setups or restricted designs. Tension grows because market options seem limited.

For small-run orders, using available stock materials2 is often the most cost-effective approach. This allows brand customization with minimal overhead while retaining personal style.

When I first encountered a small boutique request, they wanted only a hundred pairs of slippers. They loved bold prints, but the cost to create custom fabrics from scratch was too high. Instead, we worked with available stock materials and carefully coordinated colors, patterns, and brand labels. This minimized surprises, reduced costs, and simplified production. I guided them through each color choice. I explained that we source stock from major local markets where suppliers set minimums that fit small runs, which leads to more possible designs without heavy commitment2.

This approach adheres to real-world constraints. Many big suppliers have high minimum order quantities3 on raw materials. If we cannot meet those numbers, we must leverage what the market already provides. We often rely on existing polyester or cotton blends that offer consistent quality. We then apply brand labels, embroidery, or direct prints if the material supports it. That helps keep lead times low. Meanwhile, we can focus on brand identity by selecting the right color or pattern from available stocks. We gain control over design details without paying for massive custom fabric runs. This method remains an easy gateway into the world of custom footwear production for smaller orders2.

Does Limited Technical Customization Restrict Creativity?

We worry that limited processes might hold us back. We want creative freedom for brand expression. It feels scary to compromise on style for budget or practicality.

Limited technical customization4 often focuses on digital printing or small-scale embroidery on stock fabrics. This keeps costs predictable while allowing personal design touches.

I once assisted a designer brand that demanded a specific floral motif on slippers. They only planned a few hundred pairs, so printing high volumes of custom fabric was not scalable. Instead, we pivoted to a digital printing process that works on polyester materials. Because polyester was readily available in the market, we bypassed the large minimum order for custom fabrics2. We achieved a bold, crisp pattern that matched the brand’s aesthetic.

Technical customization can still offer many possibilities, though it’s bound by the base material’s properties. For example, some prints require a thick cotton weave, while others need a silk-like finish. Printing on short fur or silky fabrics can be possible, but the technology is more specialized and might increase costs. The key is balancing creativity with realistic production parameters. Reduced complexity helps the brand maintain quality without overspending. Over the years, I found that even minimal customization can make a product feel unique by tweaking color schemes, patterns, and subtle design elements5, including those on furry slippers. By focusing on these details, we can carve out a distinct space in the market without going beyond technical limits.

Is Bulk Customization the Right Choice for Large Brands?

Large orders bring different challenges. We may get lost in huge production lines, big supplier demands, or steep minimums. That often causes stress.

Bulk customization6 unlocks full material control. Brands can request specialized fabrics, custom colors, and exclusive textures. It requires higher order quantities but offers almost limitless design freedom.

I remember guiding a major retailer who wanted 15,000 pairs of fur slippers with unique shapes and plush textures. They preferred exclusive fur from dedicated suppliers, which demanded purchasing at least 3,000 meters of that custom material. By agreeing to these large minimums, the brand gained the freedom to choose any color palette and specify the density of the fur2. This high quantity let us partner with a slipper factory well-versed in luxury lines, ensuring consistent quality.

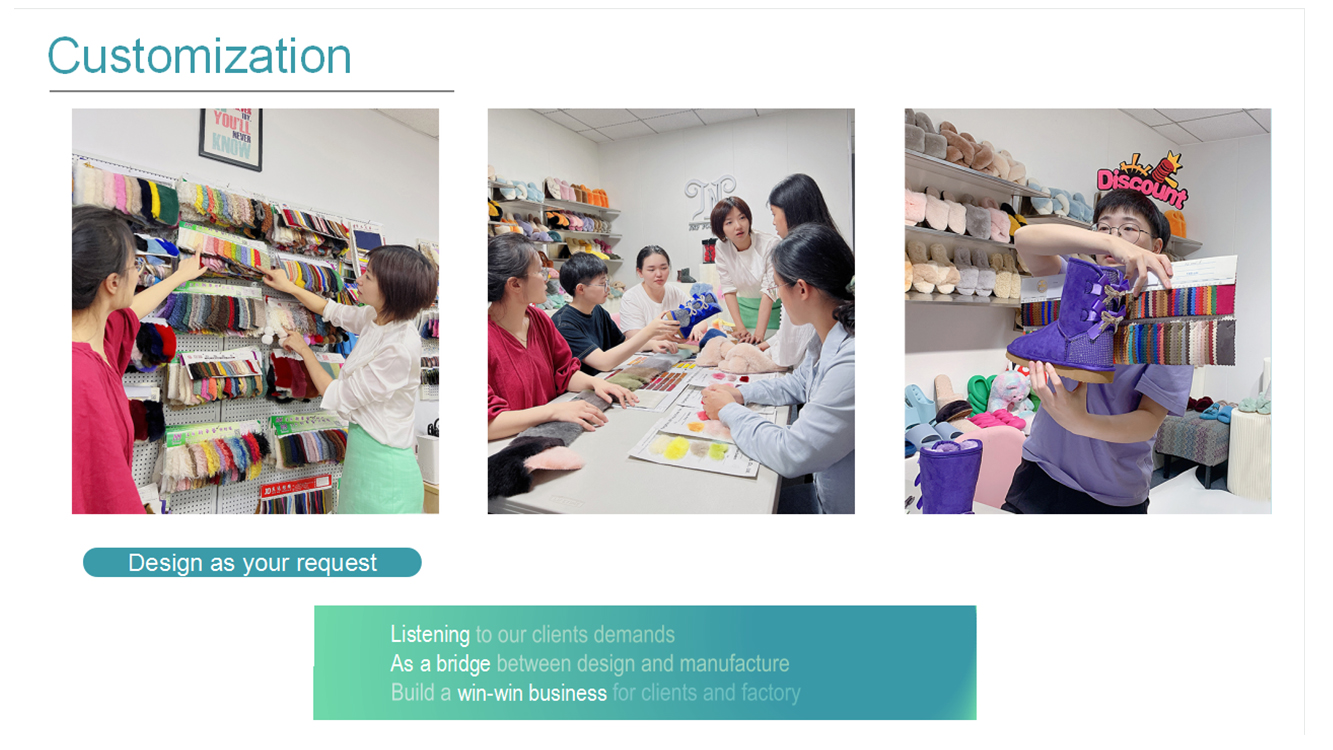

Bulk customization involves deeper collaboration with material suppliers. We share detailed specifications and maintain consistent communication with design teams. In some cases, we source eco-friendly or renewable materials7, such as wool, aligning with consumer demands for sustainability. Large-volume orders also unlock advanced methods, including elaborate embroidery or fully original sole designs. The brand invests more upfront, but they get unmatched brand identity across big campaigns. By planning thoroughly, large clients maximize design variety while reducing per-item costs. When done right, this synergy raises brand value and product distinction in the market.

Are There Special Considerations for Different Buyer Types?

We often meet different brand owners with unique challenges. We might wonder if big or small players have varied custom needs. It can be confusing.

Each buyer has distinct pain points8, from complex design demands to small quantity blocks. Understanding their priorities shapes effective customization strategies.

I have collaborated with three main buyer types. First, there are designer brands like J. in the USA, with high SKU counts and complicated custom demands. They seek eco-friendly materials, original shapes, and reliable communication from a supplier8. They often run into repeated confirmations due to internal complexities. We use checklists and structured workflows to prevent mix-ups. This approach improves clarity and on-time delivery.

Second, I see online trendy brands like R., targeting young consumers with fun, limited-run collections2. They crave quick response times and are open to bold prints. However, they struggle when big factories reject small quantities. We handle this by using stock fabrics and faster printing methods, helping them capture trends at the right moment.

Third, distributors like A. often seek classic wool footwear in large volumes. They face rising production costs and slower markets, so they look for practical solutions that balance tradition with new styles7. They sometimes mix standard lines with small runs of experimental designs, staying flexible in a changing market. Each buyer type prompts us to customize our approach, whether that means focusing on quick-turn stock materials, advanced manufacturing, or a balanced hybrid.

Conclusion

I have learned that customization follows quantity. By balancing order size, material choices, and brand needs, we can create unique products that align with any vision.

Footnotes

-

Custom footwear production involves matching quantity requirements with available materials and processes. Understanding this helps brands navigate options efficiently. ↩

-

Stock materials allow small brands to customize with low overhead, offering a practical entry point into footwear customization. ↩ ↩ ↩ ↩ ↩ ↩

-

High minimum order quantities (MOQs) from material suppliers often limit customization options unless orders are large. ↩

-

Limited technical processes such as digital printing or embroidery help maintain flexibility without overwhelming costs. ↩

-

Subtle design details like color combos or trims can personalize products even under production constraints. ↩

-

Bulk customization offers full control over fabric, design, and branding—ideal for brands with high-volume orders. ↩

-

Eco-friendly materials such as wool are increasingly requested by large brands to meet sustainability goals. ↩ ↩

-

Different buyer types (designer, e-commerce, distributor) have unique customization needs and constraints—knowing these helps in planning production strategies. ↩ ↩